Desktop

- MENU

-

About Us

-

- Harris & Howard Bespoke Tailors

- About Harris & Howard

- History

- Visiting Service

- Location

- International Scope

-

-

Bespoke Tailoring

- Alterations

- Weddings

-

Bespoke Shoes

-

Online Shop

- Contact Us

Tablet

MENU

- Explore

-

About Us

-

Bespoke Tailoring

-

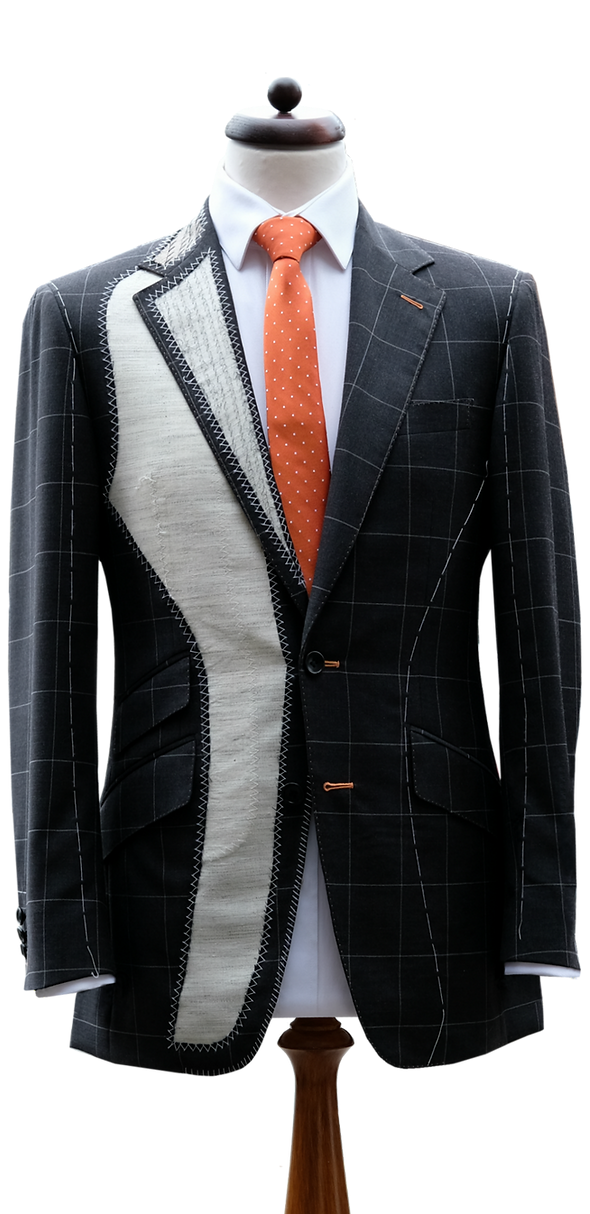

- The Details

- Bespoke Tailoring

- The Process

- Garment Care

- Bespoke

- Jackets

- Trousers

- Shirts

- Waistcoats

- Overcoats

- Bespoke Occasions

- Country Wear

- Formal Attire

- Casual Wear

-

- Alterations

- Weddings

-

Bespoke Shoes

-

Online Shop

- Contact Us

Mobile

MENU

- Explore

-

About Us

-

Bespoke Tailoring

-

- The Details

- Bespoke Tailoring

- The Process

- Garment Care

- Bespoke

- Jackets

- Trousers

- Shirts

- Waistcoats

- Overcoats

- Bespoke Occasions

- Country Wear

- Formal Attire

- Casual Wear

-

- Alterations

- Weddings

-

Bespoke Shoes

-

Online Shop

- Contact Us